Top Risks in Shipping and How Tech Is Helping Solve Them

Table of Contents

Shipping and freight industry is one of the oldest industries in existence. They contribute to the world economy greatly. It is the driving factor for the trading and trade relations among the nations. Many risks are associated with it owing to its importance globally.

Some of the common risks that can affect a business are meeting delivery commitments, the safety of the shipment, the safety of the mode of delivery, efficiency in booking and tracking operations, etc. With the advent of technology, some of the other issues that the industry faces are technical uncertainty, rapid change in technology and cybersecurity. Increasing customer expectation and competition drives any company to venture into new domains keeping in mind the quality of services do not degrade in the process.

Key risk areas associated with Shipping and Freight industry

1) Freight Tracking

Tracking of freight means the time taken by the shipment to reach the customer/destination address from the warehouse/ source address. The average delivery time should be calculated so that the company has the track of its performance region wise and shipment wise. Tracking is one functionality that is available to all the stakeholders involved in a particular shipment order fulfillment process, so its correctness is of utmost importance. Any error or wrong information can result in huge losses if it is the carrier and reduction in the value of the company if it is at the customer end.

(adsbygoogle = window.adsbygoogle || []).push({});

The shipment delivery time should be precise and the same should be informed to customers. Improper depiction of shipment tracking details to the customer can lead to dissatisfaction. The tracking ID should be system generated and programmed in a way that it generated global naming convention across the company’s various offices. The return policy is another functionality that needs to be hassle-free, many customers use the services by first viewing the return policy, and if it is not user-friendly, they discard the idea to avail the services.

2) Cargo Capacity Monitoring decides the cost

The vehicle in which the shipment reaches its destination from its source is it truck, ship, flight or any other medium, it’s capacity check is another issue that the shipment company faces. The right vehicle size for the shipment going to a particular location decides the price charged by the carriers. Any extra space or shortage of space leads to extra cost.

So, optimum utilization of capacity is a very important and tedious task if done manually.

3) Communication

Vehicle-to-Vehicle communication is an important aspect of communication is the shipping industry apart from the intracompany communications there is communication with the customers and other stakeholders.

Any gap in communication can lead to serious losses both in terms of value and in terms of money.

4) Contracts, documentation

Improper documentation of insurance papers, cargo space, shipping and export documents by freight forwarders can cause unnecessary delays and incorrect delivery. This can hugely affect the customer expectation of quality service. Documentation is much prone to error even when there are automated systems generate it since there is a certain level of human intervention involved. Manual creation, verification, and sharing of documents can face various communication issues starting from poor internet connectivity leading to delays, incomplete documents, and human errors.

The documentation plays an important role especially in case of international shipments and exports as the port authorities, the carriers, the sender and the receiver need to have all the required contracts, agreements based on the regulatory frameworks of the countries of both the parties.

5) Data and Information management

A lot of data is generated in a shipping company in the form of customer details, vendor and carrier details, shipment details, contracts, and other documents.

This data can be in the paper form or online but securing it from mishandling is the primary concern.

6) Technical, Geographic and Weather Hazards

Technical hazards include any defect or issue with the machinery, mode of transport or any other physical automated tool that can hamper the work and make it slow. Geographic hazards can be the road conditions in case of road shipments, air conditions in a particular area for air transport and icebergs, coral reefs or sandbars in case water cargos.

Weather hazards can be natural disasters which can happen anywhere anytime causing loss of the entire shipment and heavy monetary losses

7) Transportation issues

The shipments and cargos need a mode of transport to reach from one place to another so this is another area of concern. Trucks, flights, and ships are the three main modes of transport used by the shipping companies. Unavailability of a right-sized truck ship or carrier at the right time is one major issue that the companies face.

Another can be improper communication between the means of transport of the carriers due to lack of connectivity or other things in case the shipment has to travel through multiple modes of transport can be the next big problem.

8) Dispute in payments

Many monetary transactions happen in a shipping company. The shipment collection from customers to shipment delivery involves a huge amount of paperwork and the associated payments.

In the manual process, intermediary handles most of these payments. This increases the cost and there are chances of human error or fraud.

Technological Solutions

1) Big Data

In the case of geographic hazards, modern navigation techniques like GPS can be used to know the possible alternate routes for road, air or water transport to take the shipments. Big Data can be used to analyze this GPS information to calculate the cost of the alternate routes and providing a solution if diverting the path is cost effective or not.

In addition, fuel can be saved in case of road transport where instead of the truck waiting in the traffic and burning fuel can be re-routed to a different path.

Big Data can also use for analysis of the shipping data and information. It can ease the management of this huge data that is generated

2) IoT

IoT sensors can be deployed to the shipping vehicles, shippers and in the shipping companies so that the capacity issue can be solved. Space taken by the existing system can be determined and accordingly the cost so that the right sized system can be deployed depending on the size of the shipment. All these data can be then stored in the Blockchain.

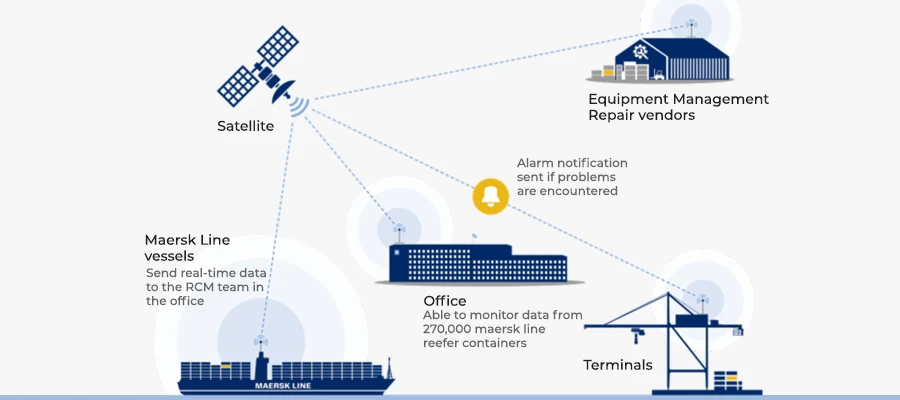

Another benefit of using IoT combined with Blockchain is vehicle-to-vehicle communication. This helps to form a network of devices placed in the vehicles that are part of the same shipment, they form a platoon and can directly communicate among themselves thus improving safety, fuel efficiency and reducing time and cost. Again, all this data can be stored and validated on the Blockchain and can streamline the operations of the company. Shipping containers have also become smart; these can communicate the data it has like its location, its condition, and the condition of the cargo. This enables real-time monitoring.

IoT can be used for dealing with technical hazards. The sensor in the devices can warn before a failure occurs. This not only gives time to repair or replace but also saves time and cost in case the failure occurs midway during the process of shipment delivery. These sensors can predict of any upcoming technical issues.

(adsbygoogle = window.adsbygoogle || []).push({});

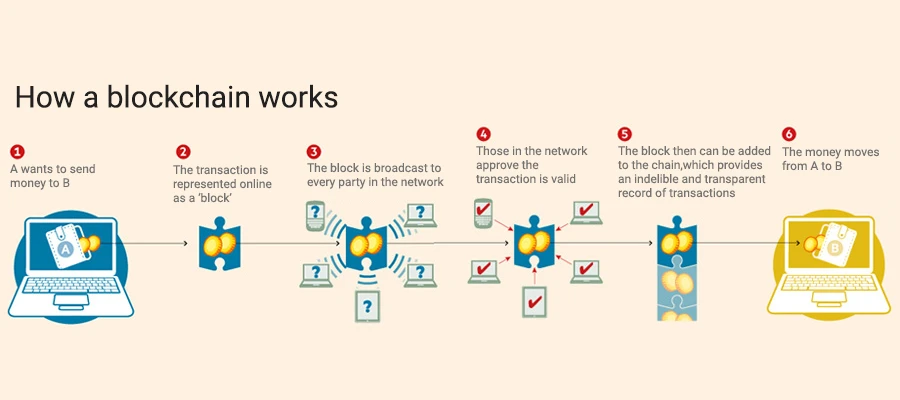

3) Blockchain

The first issue that Blockchain solves is unnecessary paperwork or the risk of improper documentation. The Blockchain enabled platform can facilitate the coordination of various interrelated contracts, agreements, and insurance documents. By using smart contracts and approval, a system for contracts and custom clearance the processing time can reduce at checkpoints adding to the efficiency of the system.

The second issue is of tracking and shipping, with the increasing customer demand for faster delivery (same-day or next-day delivery) the conventional shipping and tracking procedures cannot scale to this level so, Blockchain provides an immediate solution for authentication and order tracking.

Smart Contracts offered by Blockchain helps reduce cost since it eliminates the need for intermediaries. These are self-executing tasks programmed through Blockchain in such a way that these are executed when a condition is met. An example of this can be if the company has to pay to the shipper after the shipment reached its destination it can program the smart contract in such a way that the payment is released as the notification for delivery is confirmed and a similar notification is generated as the shipped has the payment.

As most of the shipment, the fulfillment process relies on paper-based systems that involve multiple channels of approval causing loss chances of fraud. Using Blockchain, smart contracts can replace the administrative procedures thus, reducing cost and possibility of error.

Data, as it is called the new gold, can be muddled, manipulated, duplicated and deleted. The huge amount of data is generated which is utilized for gaining useful insights. Using Blockchain the entire network can validate and authenticate the data and it cannot be subject to tampering. Another form of data that is generated in a shipping company is the shipper’s data that the shipper can load in the system and it is time stamped and can be verified using a decentralized system from anywhere anytime. Thus, data integrity will be maintained.

4) RPA

Robotic Process Automation can be considered as the latest of all technologies that can be used by the shipping companies. It provides resolution to almost all the issues and risks that the industry faces.

The shipment tracking and scheduling can be automated using RPA. RPA can extract shipping details from the emails or the platform used to create a shipment and can provide pick-up and delivery times in customer or carrier portals all with the robots and zero human intervention.

Another issue is the payment issue, regular follow-ups involving multiple systems make this process slow and error-prone. RPA has the ability to integrate these systems and streamline this process. It can integrate the billing and payment system of multiple carriers and other third-party players and automate the entire order-to-cash process.

Auto-mailer facility provided by RPA can send notifications to the customers, carriers and other stakeholders through the system about the status of the order without any manual process. This leads to effective communication and reduces the communication gap.

Data and information management can also be done. Re-keying, manually attaching data to invoices and cutting -pasting can be eliminated using RPA. It automatically extracts data, attaches attachments to invoices and updates the portals to inform customers within seconds rather than days.

Conclusion

Shipping industry contributes to 90% development in the major economies in the world. Any mismanagement in dealing with the risks discussed above can lead to issues in the entire chain of operations of a shipment delivery process. Since every process in the shipment order-to-cash process is dependent on one another, the overall impact of a loophole would be far greater than expected. Many industries now understand the power and importance of data in this era of digitization. Leveraging the power of data insights can increase the pace of industrial growth using associated technologies leading to improvement in the efficiency of operations.

Shipping and freight industry has been slow in adopting technology compared to other industries but the exponential growth in market demands has led to innovations. Companies and nations as a whole know that the cost incurred to include technology would be less compared to the cost in case of a failed shipment or delay in service or any event that causes customer dissatisfaction. The benefits the companies gain by efficient risk management converts to more satisfied customers, better quality services, continuous expansion in line of business, competitive pricing, faster delivery, safer shipments, improved communication channel, proper documentation, better space management in cargo and warehouses to name a few.